Alongside these launches, Sormac will showcase the latest equipment upgrades and demonstrate equipment for the processing of carrots, onions, potatoes peppers, lettuce, melons, and more.

Designed to meet high hygienic standards, reduce labor, and deliver premium output quality, Sormac introduces the fully automatic robotic pepper corer PCR and the versatile dice cutter DC-145. The company also debuts two imaging driven solutions. OptiView, is a hygienic camera system that aids production quality, process control and troubleshooting at the production site. Next to that Sormac introduces OptiPro, a visual automation system for processing lines, that monitors and recognizes whether the processed product meets the given settings. Both solutions contribute to higher productivity and production quality.

At the fair, visitors can also see the newly redesigned vertical vegetable centrifuge FC-540 and the upgraded slice and wedge cutter FS-3600 MultiSystem.

“We are delighted to invite all fresh produce processors to join us at Fruit Logistica, stand C-40 in hall 1.1, to explore our latest innovations, experience live demonstrations, and connect with our experts,” says Roy Lemmen, Sales Director at Sormac. “We look forward to sharing knowledge and network with our customers in the fruit and vegetable sector.”

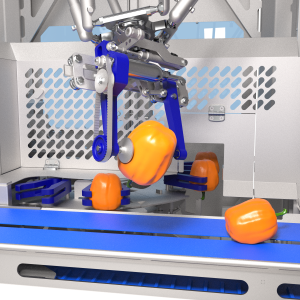

Fully automatic pepper processing

Designed for maximum efficiency and hygiene, Sormac introduces PCR, a robotics-aided pepper core that processes bell peppers from singulation and orientation to de-coring and portioning in a continuous and fully automated way.

The PepperCorer Robotic singulates the peppers from bulk, visually detects the product position and, with the help of a robotic arm, picks and places the peppers in the grippers of the decoring-and-cutting station. Similarly to the well-established Sormac PepperCorer PC-55, the entire seed core and stem are cut and suctioned off by vacuum and separated to waste stream. Optionally, the peppers can be cut into slices, rings, wedges and cubes of up to 24 pieces. The PepperCorer Robotic has a capacity of up to 2.500 pieces per hour depending on product type, quality and speed of supply. The new machine offers automation, high processing quality and reliable operations and it significantly reduces manual labor.

Ease-of-use and premium dicing quality

Expanding its technology offer in cutting, Sormac introduces the new 3D vegetable dice cutter DC-145. Co-developed with Foodcons, the new machine is versatile and easy-to-use and offers high precision cutting quality. It supports dice, stick and slice cuts in various sizes.

RELATED NEWS: Sormac expands delivery programme with Felcon machines

With its 400 mm drum diameter, the machine features the largest drum in its class, which promotes high productivity and a gentler cutting process. Thanks to the touchscreen HMI, operators will be able to set up the slice thickness digitally with high precision, without the need of mechanical adjustments on the machine. The new dice cutter has a capacity of 6,000 kilogram per hour depending on the application.

Camera monitoring for processing plants

Sormac introduces OptiView, a hygienic camera system for vegetable processing production plants. The system incorporates imaging technology and robust hardware to deliver reliable and accurate information, enabling food processors to enhance their operations, help servicing and trouble shooting. OptiView features real-time observation of critical production stages for process control and quality assurance. In addition, the video stream can be recorded and easily accessed via the Sormac remote portal. The system allows image blurring of isles or other production areas in order to safeguard privacy regulations.

Visual product recognition for processing lines

Designed to optimize the production process and minimize manual interventions, OptiPro detects whether the processed product meets the pre-programmed recipe and automatically sends signals to the control unit of the line, in case actions are needed. The system is suitable for recognizing leafy vegetables, including those grown in controlled environment agriculture. When the crop reaches the OptiPro, the system utilizes one or more cameras to capture detailed images of the product. These images are then processed using deep learning software developed by Sormac. The capacity of OptiPro is precisely aligned with the throughput speed of the processing line.